Microdispensing systems (MDS) - Highest precision and speed

The microdispensing systems of the MDS 15xx, 32xx, 30xx and 35xx product series from VERMES Microdispensing set new standards in contact free dispensing technology. They offer exceptional speed and accuracy, making them the ideal solution for modern manufacturing processes.

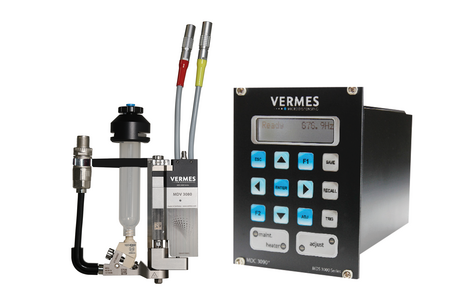

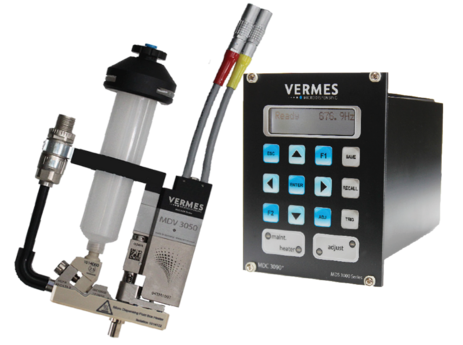

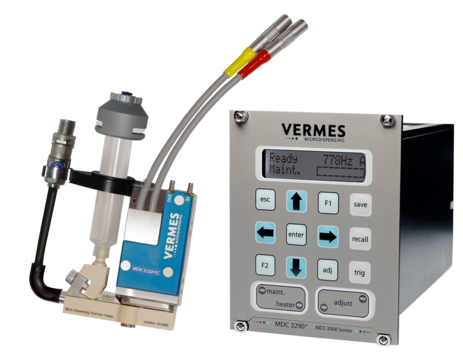

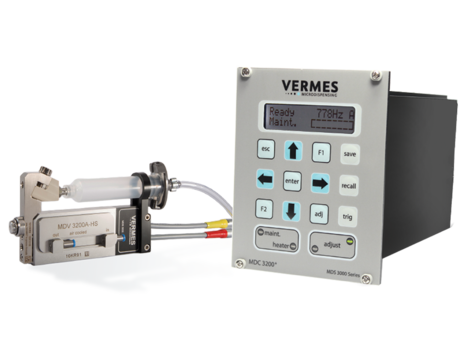

Components of a microdispensing system

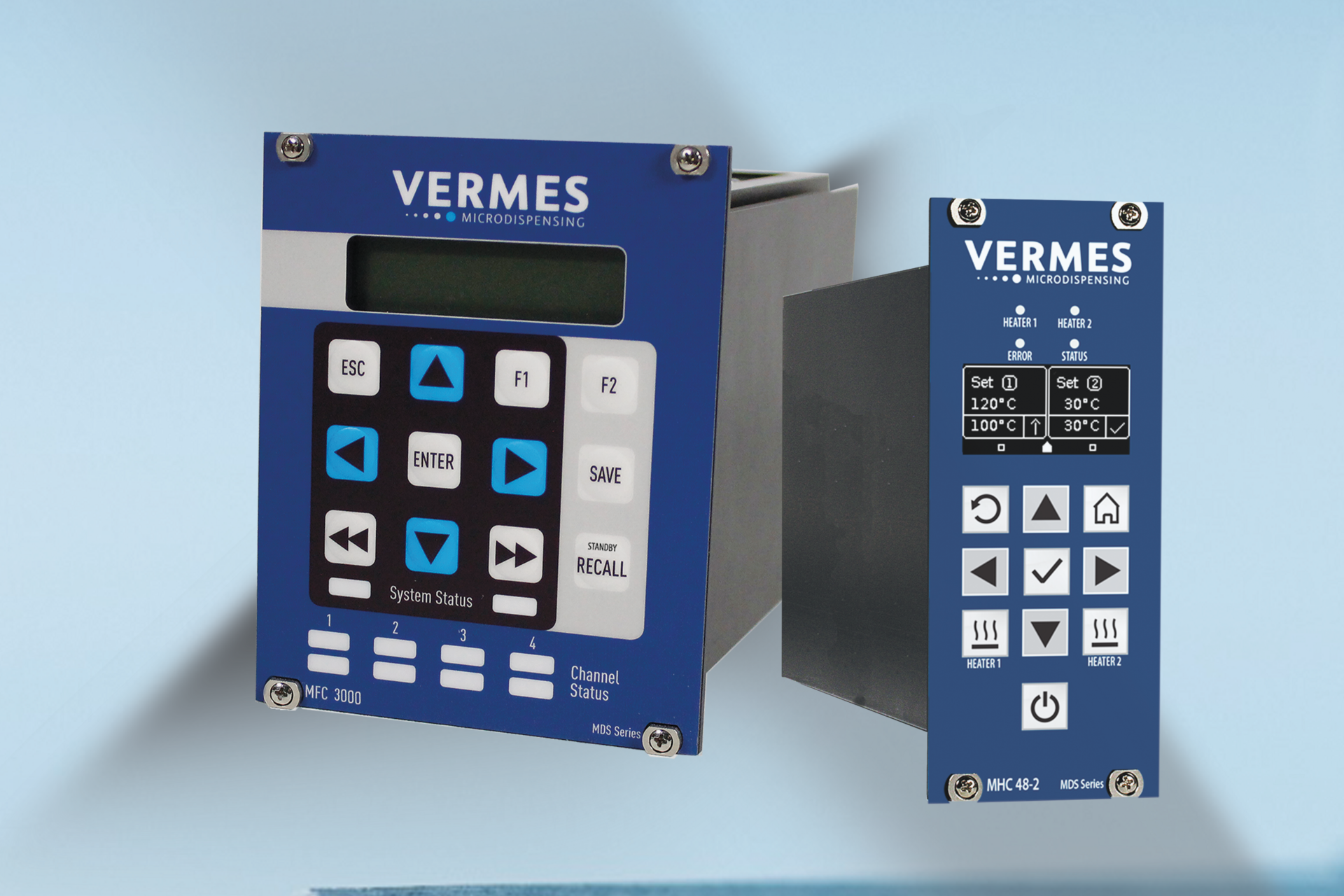

At VERMES Microdispensing, a MicroDispensing System (MDS) consists of two central components:

- the MicroDispensing Valve (MDV)

- the MicroDispensing Controller (MDC)

This combination enables the precise control and dispensing of very small quantities of liquid - contactless, fast and economical.

Indispensable for modern production processes

Advances in miniaturisation are making contactless microdispensing systems indispensable - they ensure precise, repeatable and reliable dispensing for modern manufacturing processes.

With microdispensing systems from VERMES Microdispensing, you are ideally equipped to solve even the most demanding dispensing tasks efficiently and precisely.

Micro Dispensing Systems with PX2 Technology

MDS 3050

- Powered by VERMES PX2 - Piezo Xtreme 2 Technology

- Fast and Comfortable Configuration with Side Adjust

- Frame Technology Provides exceptional Stability and Resistance to Expansion and Break Elongation

- Effortless Handling and Easy Maintenance

- Supports high-volume, automated, fast and highly accurate production processes

Micro Dispensing Systems with Piezo Technology

MDS 3000 Series

Micro Dispensing Systems with Dynamic Shockwave Technology

MDS 1000 Series

DST

Dynamic Shockwave Technology

Pioneering a new actuator principle

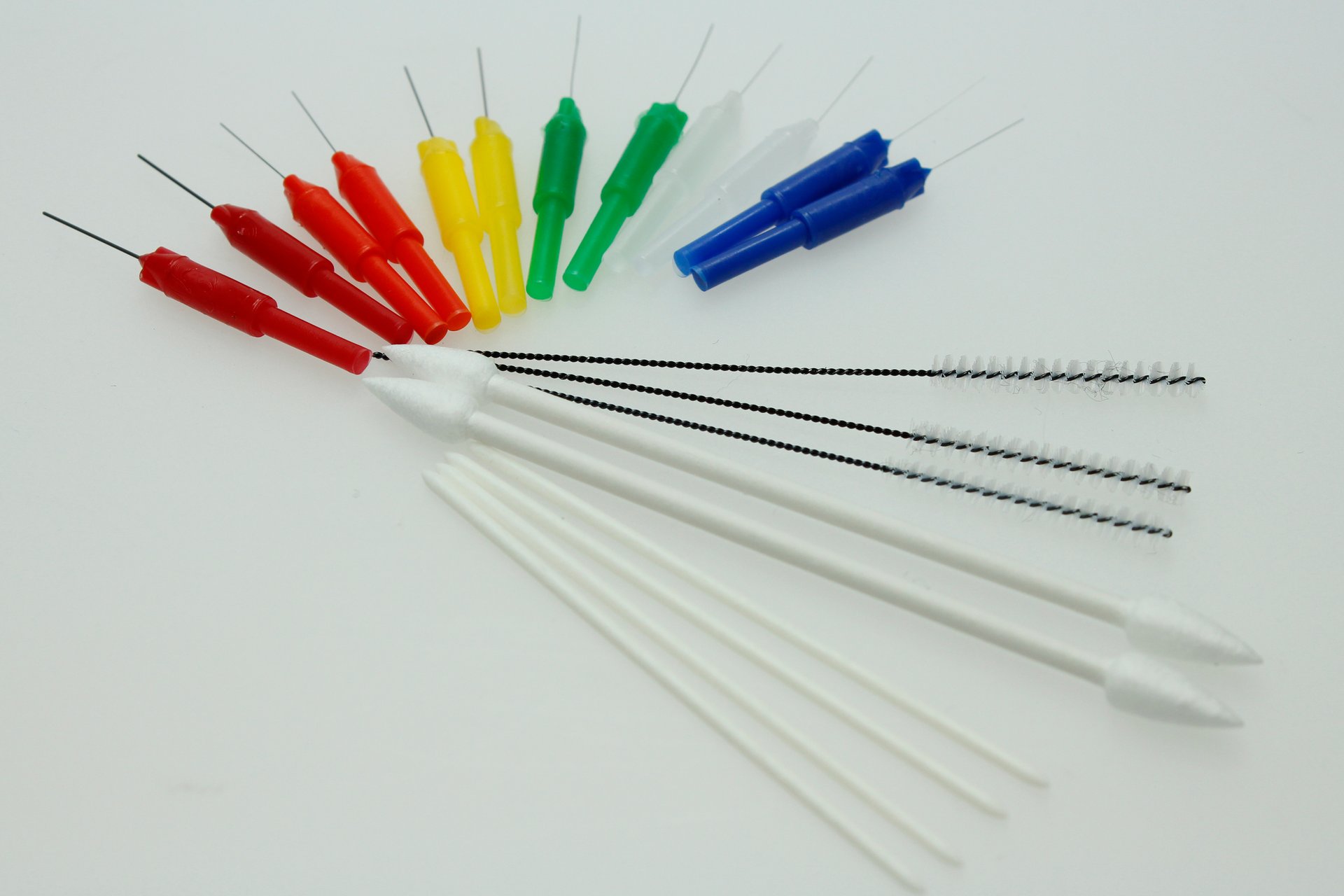

Modular parts for every application

A suitable solution for each individual application

The valves of the VERMES Microdispensing MDS Series can dispense media with viscosities of up to 2,000,000 mPas and droplet sizes of micro-, nano- and subnano-liter. We supply all industries; (e.g. microelectronics, semiconductors, consumer electronics, LED / LCD, medical technology, pharmaceutics, automotive).

© copyright 2025 VERMES Microdispensing GmbH