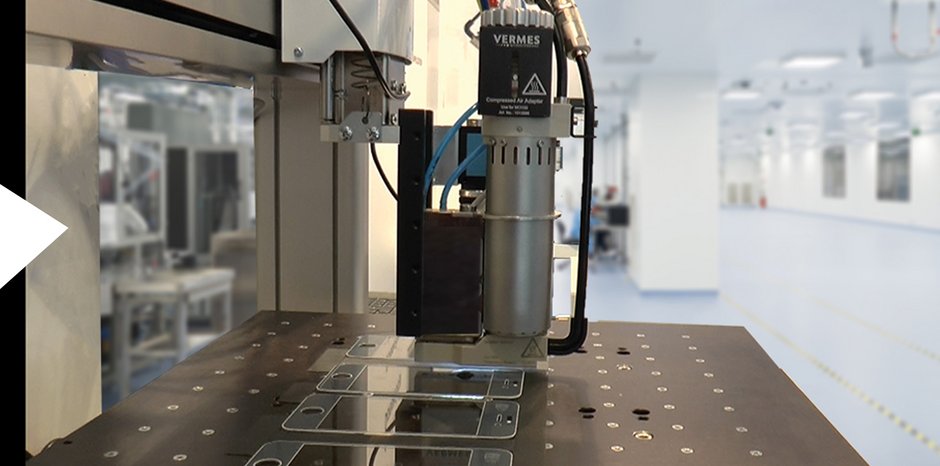

VERMES Special Machinery

Special machinery, test and analysis systems, from device prototyping to series production.

Read more>

With our comprehensive knowledge, we can offer you the best and most appropriate microdispensing products, services, and solutions that are perfectly tailored to your production process.

Automotive

Automotive Industry

The automotive industry uses the VERMES Microdispensing Systems of the model lines MDS 3280 and MDS 3250+FC mainly in the car electronics production.

This includes:

- roof manufacturing

- door coverings

- camera module manufacturing

- manufacturing of window lifts.

The main advantages of the VERMES Microdispensing Systems stem from the versatile usability including the very powerful dispensing valves and from the ability to dispense large numbers of very small and precise dots in a very short time – in other words, high speed even for very precise applications.

Consumer Electronics

Consumer Electronics Industry

The consumer electronics industry uses several VERMES Microdispensing product lines. This includes the MDS 1000 Series that is based on the unique DST - Dynamic Shockwave Technology.

The industry relies also on the models of the MDS 3000 Series (mostly MDS 3280, MDS 3200+CP or MDS 3200+-AC) which are used i.e. to grease safety switches with very high viscous grease or to dispense conductive paste onto thermocouples.

Other usages include fixing of inductor wires, automatical bonding of anchor plates, magnetical fixing in the electric motor manufacturing and ferrite bonding.

In gadget and in mobile production hot melt dispensing is one of the major production parts that is usually performed with the MDS 3280 Hot Melt System.

The extraordinary power of the piezo-based systems and the outstanding actuator principle of the DST-based systems both offer a z-axis independant dispensing with its advantages.

Semiconductor

Wafer and Semiconductor Industry

The wafer and semiconductors industry relies on the models of the MDS 3000 Series. In the semiconductor industry, the VERMES Microdispensing Systems of the model lines MDS 3280, MDS 3250+ FC and MDS 3200+ are often used for underfill applications.

The main advantage of these dispensing systems stems from the freedom in design. The special nozzle geometries allow the dispensing valves to reach the components to be underfilled with particularly high precision.

This enables an optimal package design due to the minimal distance between the chips.

Optoelectronics

Optoelectronics Industry

In optoelectronics the VERMES Microdispensing Systems are employed in the manufacturing of applications such as automatic access control systems, telecommunications, medical equipment, and more.

In the LED (Light Emitting Diode) industry, for example the MDS 3000 series is used to dispense silver conductive adhesives to bond chips.

The valves have the advantage of being able to dispense a large number of small, precise dots in a short amount of time. The systems are also used for the socketing of filled and unfilled silicones of the already connected chips.

The main advantages stem from the high output with maximum precision.

Photovoltaics

Photovoltaics / Solar Cells

In the solar cells and photovoltaics industry our VERMES Microdispensing Systems of the piezo-based model line MDS 3280 and of the DST (Dynamic Shockwave Technology) based model line MDS 1560 are used to dispense silver conductive adhesives and to bond contact bands.

The main advantage of these dispensing systems stems from the reduced amount of glue materials to be used and the high precision and performance that they achieve.

Medical/Pharmaceutical

Medical and Pharmaceutical Industries

In the fields of medical technology and pharmaceutics the VERMES Microdispensing Systems offer a perfect solution for low to medium viscosity applications.

The systems of the MDS 3050 Series are used for a wide range of applications including life science, medical diagnostics, pharmaceuticals, e.g. anerobics, water-based cell and protein solutions.

They are for example dispensing enzyme solutions onto blood sugar test strips.

The major advantage of these dispensing systems stems from the maximum precision even when dispensing only very small amounts of the medium.

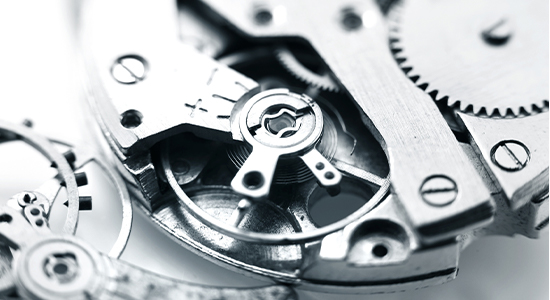

Precision Mechanics

Precision Mechanics Industry

In the watch and precision mechanical industry the VERMES Microdispensing Systems of the model lines MDS 3050 and MDS 3280 are used to dispense synthetical precision mechanical oils onto bearings and shaft journals in mechanical watches.

The main advantage of the VERMES Microdispensing systems stems from the possibiltiy to dispense very small drops of grease, oil or glue contact-free with precise control of the exact amounts of dispense medium.

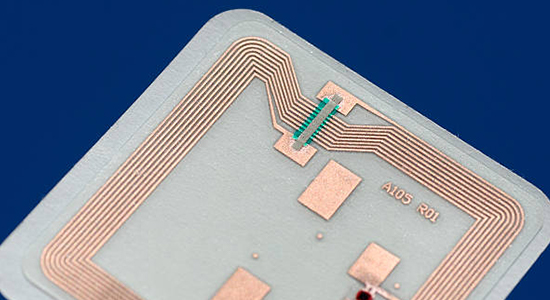

RFID

RFID Industry

In the RFID industry (Radio-frequency identification) VERMES Microdispensing Systems of the model line MDS 3000 and or MDS 1000 are used to bond RFID chips to tags.

With highest speed and reliability the VERMES dispensing systems allow to reach the desired output of the small RFID components for each machine.

The main advantage of the VERMES microdispensing systems stems from their robustness, which is caused by the extraordinary power of the Piezos or the DST (Dynamic Shockwave Technology), the z-axis independent dispensing and the low total cost of ownership (TCO).

Industrial Electronics

Industrial Electronics

In the electronics industry the VERMES Microdispensing Systems of the model line MDS 3250 and MDS 3280 are used to grease safety switches with very high viscous grease or to dispense conductive paste onto thermocouples.

Other usages include fixing of inductor wires, automatical bonding of anchor plates, magnetical fixing in the electric motor manufacturing and ferrite bonding. The main advantage of the VERMES microdispensing systems stems from their versatility.and the z-axis independant dispensing.

For Surface Mounted Technology - SMT the VERMES Microdispensing Systems of the low and medium viscosity model lines and for the high and highest viscosity model lines are used to aid the assembly in the conductor plate manufacturing, to dispense conductive adhesives (silver, nickel…) and other SMT adhesives, to encapsulate parts, to underfill chips, for conformal coating on the board, for Dam & Fill, Flip Chip, COB, and many other processes.

The main advantage of our dispensing systems in all these cases stems from the possibility of very powerful dispensing of precise dots with high speed.

Applications

We support you with:

- thorough analysis of your dispensing application

- technical consultation and support

- individual operator trainings

- intensive guidance during the whole process

- specific and competent maintenance service

Dispensing different media exact, fast and contact free with the well established microdispensing valves from VERMES Microdispensing. Our innovative dispense technologies are continuously improved and enhanced by our research and development team.

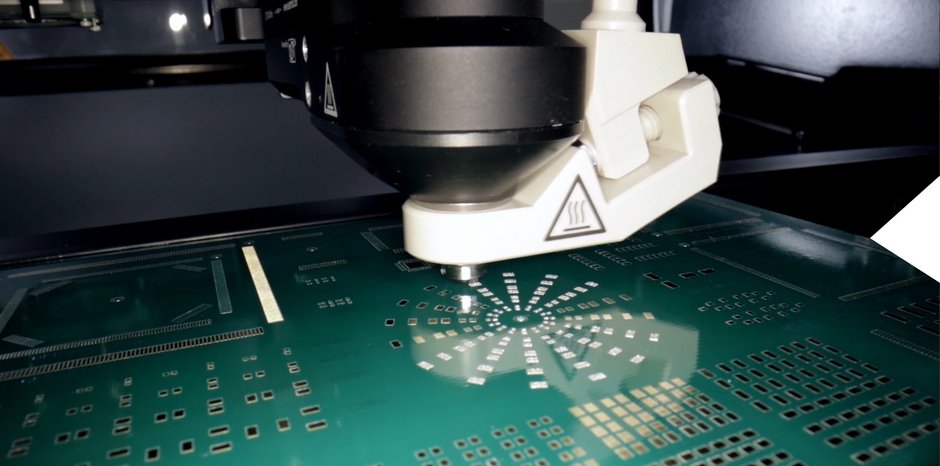

Solder Paste Dispensing with the VERMES MDS 1560 - DST System

At VERMES Microdispensing, we extensively study the behaviour of various solder pastes and adapt our systems to achieve the best possible solution for our customers’ applications. With the MDS1560 - powered by DST dynamic shockwave technology VERMES Microdispensing offers a solution to reliably dispense Solder Pastes from Type 5 onward.

Hot Melt Dispensing with the VERMES MDS 3280 Series

The VERMES Microdispensing Hot Melt System is an optimal solution for the dispensing of polyurethane-based hot melt adhesives. In combination with the cartridge heater and nozzle heater the system can precisely adjust to the requested temperature. The exceptionally fast piezo actuator is operated with extremely fast opening and closing cycles . The precise valve stroke and force dispenses hot glue in ultra-fine dots/lines.

Application Examples - exact dispensing of liquids -

Adhesion

Adhesion

The bonding technique gluing becomes more and more important within the field of electronics. The tendency to miniaturize modules, devices and end products is the main reason. Adhesives are suited ideally to bond different materials in small spaces - and to do it fast, secure, durable and cheap. The flip chip technology is a prime example.

- Anaerobics

- UV Curing Adhesives

- Cyanoacrylates

- Electrically Conductive Adhesives

- Thermal Conductive Adhesives

- Hot Melt Adhesives

Anaerobic Adhesives

| Adhesive | Example application | Recommended microdispensing system |

|---|---|---|

| DELO-MS-DB135 | Fixing of metallic components | MDS 3050 anaerobic / MDS 1560 anaerobic |

| DELO-ML 5302 | Sealing of thread connections | MDS 3050 anaerobic |

| Loctite 648 | Fixing of metallic components | MDS 3050 anaerobic / MDS 1560 anaerobic |

| Loctite 661 | Fixing of metallic components | MDS 3050 anaerobic / MDS 1560 anaerobic |

UV Curing Adhesives

| Adhesive | Example application | Recommended microdispensing system |

|---|---|---|

| Loctite 3103 | Bonding of plastics | MDS 3050 |

| Loctite 3105 | Bonding of plastics | MDS 3050 |

| Loctite 3106 | Bonding of plastics | MDS 3050 |

| Ormocomp | Glueing in space of micro lenses | MDS 3050 |

| DELO-Katiobond 4578 | Sealing and fixing of electronic components | MDS 3050 |

| DELO-Photobond PB437 | Glueing of displays | MDS 3050 |

Cyanoacrylates

| Adhesive | Example application | Recommended microdispensing system |

|---|---|---|

| Kisling Ergo 5901 | Attaching very fine structures | MDS 3050 |

| Loctite 4062 | Bonding of Metals | MDS 3050 |

| Loctite 406 | Bonding of plastics | MDS 3050 |

| Loctite 438 | Bonding of plastics | MDS 3050 |

| Loctite 4304 | Bonding of plastics | MDS 3050 |

Conductive Adhesives

Electrically Conductive Adhesives

| Adhesive | Example application | Recommended microdispensing system |

|---|---|---|

| Sumitomo CRM1033b | Fixing of electronic components | MDS 3200+ , MDS 3250+, MDS 3280 |

| Emerson & Cuming WCA 20614-30B | Fixing of electronic components | MDS 3200+ , MDS 3250+, MDS 3280 |

| Emerson & Cuming CE3103 WLV | Fixing of electronic components | MDS 3200+ , MDS 3250+, MDS 3280 |

| Emerson & Cuming CE3103WZV | Glueing of displays | MDS 3200+ , MDS 3250+, MDS 3280 |

| EPO-TEK H20E-PFC | Fixing of semiconductor chips | MDS 3200+ , MDS 3250+, MDS 3280 |

| EPO-TEK H20E-S | Fixing of semiconductor chips | MDS 3200+ , MDS 3250+, MDS 32800 |

| Hysol Eccobond CA3556HF | Fixing of electronic components | MDS 3200+ , MDS 3250+, MDS 3280 |

| Hysol QMI 529HT | Fixing in place of electronic components | MDS 3200+ , MDS 3250+, MDS 3280 |

| Ablebond 84-1A | Fixing in place of electronic components | MDS 3200+ , MDS 3250+, MDS 3280 |

Thermal Conductive Adhesives

| Adhesive | Example application | Recommended microdispensing system |

|---|---|---|

| Panacol Elecolit 601 | Bonding of heatsinks onto electronic circuits | MDS 3200+, MDS 3250+, MDS 3280 |

| Heraeus PD 955 PY | Fixing of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

| DELO Monopox MK096 | Fixing of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

| Loctite 3609 | Fixing of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

| Loctite 3629 | Fixing of electronic components on PCB substrate | MDS 3200+, MDS 3250+, MDS 3280 |

Hot Melt Adhesives

| Adhesive | Example application | Recommended microdispensing system |

|---|---|---|

| 3M Plastic Bonding Adhesive 2665 | Bonding of plastics | MDS 3200+, MDS 3250+, MDS 3280 |

Aqueous >

Aqueous Solutions

| Solution | Example application | Recommended microdispensing system |

|---|---|---|

| Glucose oxidase | Dispensing of sensor material | MDS 3050 |

| Agarose dissolved in water | Immersion microscopy | MDS 3050 |

| Ink | Marking of good or bad | MDS 3050 |

Profit from first class microdispensing systems and take advantage of our superior technology. Let us show you their advantages. We are your professional partner, where the ideal solution for your dispensing process is concerned.

- No damages thanks to contact free dispensing

- Exact, precise dispensing of smallest drops from 0,4 nanoliter up to several microliters

- Z-axis independant dispensing, even on uneven substrates (boards, hybrids, chips)

- Selectable shot frequency helps to avoid satellites

- You save time since you are independant of the z-axis, thanks to the contactfree dispensing

- Perfect adaptation of the valve to the dispense medium, thanks to software based programming of the tappet movement

- Precise drop forms and high repeatability of the process

Flux >

Flux

| Flux material | Example application | Recommended microdispensing system |

|---|---|---|

| Soldering Flux | Repair of solder joints | MDS 3200+, MDS 3250+, MDS 3280 |

| Multicore LF | Repair of solder joints | MDS 3200+, MDS 3250+, MDS 3280 |

| Heraeus Flux | Repair of solder joints | MDS 3200+, MDS 3250+, MDS 3280 |

Profit from first class microdispensing systems and take advantage of our superior technology. Let us show you their advantages. We are your professional partner, where the ideal solution for your dispensing process is concerned.

- No damages due to contact-free dispensing

- Exact, precise dispensing of smallest drops from 0.4 nanoliter up to several microliters

- Z-axis independant dispensing, even on uneven substrates (boards, hybrids, chips)

- Selectable shot frequency avoida satellites

- Time saving

- Perfect adaptation of the valve to the dispense medium with software based programming of tappet movement

- Precise drop forms and highest process repeatability

Lacquer>

Lacquers

| Lacquer | Example application | Recommended microdispensing system |

|---|---|---|

| Peters Elpeguard 1706 FLZ | Spraying on as protective lacquer | MDS 3050 with spray add-on |

| Peters Elpeguard SL 1309 N | Spraying on as protective lacquer | MDS 3050 with spray add-on |

| Peters SD 2692 T | Spraying on as protective lacquer | MDS 3050 with spray add-on |

| Elantas Bectron PL 4122-T | Spraying on as protective lacquer | MDS 3050 with spray add-on |

Profit from first class microdispensing systems and take advantage of our superior technology. Let us show you their advantages. We are your professional partner, where the ideal solution for your dispensing process is concerned.

- No damages due to contact-free dispensing

- Exact, precise dispensing of smallest drops from 0.4 nanoliter up to several microliters

- Z-axis independant dispensing, even on uneven substrates (boards, hybrids, chips)

- Selectable shot frequency helps to avoid satellites

- Time saving

- Perfect adaptation of the valve to the dispense medium with software based programming of tappet movement

- Precise drop forms and highest process repeatability

Oil & Grease >

Oils and Greases

| Oil/grease | Example application | Recommended microdispensing system |

|---|---|---|

| Dr. Twilich K4563/100 | Grease in the precision mechanics industry | MDS 3050 |

| Klüber Isoflex Toplas L 32 | Grease for the automotive industry | MDS 3050 |

| Klüber ASONIC GHY 72 | Grease for various applications | MDS 3050 |

| Klüber Amblygon TA 30/1 | Grease for various applications | MDS 3050 |

| Klüber ISOFLEX LDS 18 Special A | Grease for various applications | MDS 3050 |

| Klüber Constant OY220 | Grease for sintered metals | MDS 3050 |

| Moebius Synt-HP 500 | Grease in the precision mechanics industry | MDS 3050 |

| Moebius Synt-A-Lube | Grease in the precision mechanics industry | MDS 3050 |

Profit from first class microdispensing systems and take advantage of our superior technology. Let us show you their advantages. We are your professional partner, where the ideal solution for your dispensing process is concerned.

- No damages due to contact-free dispensing

- Exact, precise dispensing of smallest drops from 0.4 nanoliter up to several microliters

- Z-axis independant dispensing, even on uneven substrates (boards, hybrids, chips)

- Selectable shot frequency helps to avoid satellites

- Time saving

- Perfect adaptation of the valve to the dispense medium with software based programming of tappet movement

- Precise drop forms and highest process repeatability

Silicone >

Silicones

| Silicone | Example Application | Recommended microdispensing system |

|---|---|---|

| Dow Corning OE-6636 Optical Encapsulant | Socketing of LED materials | MDS 3200+, MDS 3250+, MDS 3280 |

| Dow Corning 6-250 Elastomer | Fixing of components | MDS 3200+, MDS 3250+, MDS 3280 |

| Wacker AK 350 | Used as lubricant | MDS 3200+, MDS 3250+, MDS 3280 |

| Wacker Elastosil E4 | Sealing of components | MDS 3200+, MDS 3250+, MDS 3280 |

Profit from first class microdispensing systems and take advantage of our superior technology. Let us show you their advantages. We are your professional partner, where the ideal solution for your dispensing process is concerned.

- No damages due to contact-free dispensing

- Exact, precise dispensing of smallest drops from 0.4 nanoliter up to several microliters

- Z-axis independant dispensing, even on uneven substrates (boards, hybrids, chips)

- Selectable shot frequency helps to avoid satellites

- Time saving

- Perfect adaptation of the valve to the dispense medium with software based programming of tappet movement

- Precise drop forms and highest process repeatability

Underfill >

Underfills

| Underfill material | Example application | Recommended microdispensing system |

|---|---|---|

| Hitashi CEL-C-3720 | Underfilling of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

| Indium Corporation NF260 | Placing and underfilling of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

| Namics U84391-1 | Underfilling of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

| Hysol FF2300 | Coating of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

| Hysol FP4654 | Damming and filling of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

| Loctite 3549 | Underfilling of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

| Loctite 3593 | Underfilling of electronic components | MDS 3200+, MDS 3250+, MDS 3280 |

Profit from first class microdispensing systems and take advantage of our superior technology. Let us show you their advantages. We are your professional partner, where the ideal solution for your dispensing process is concerned.

- No damages due to contact-free dispensing

- Exact, precise dispensing of smallest drops from 0.4 nanoliter up to several microliters

- Z-axis independant dispensing, even on uneven substrates (boards, hybrids, chips)

- Selectable shot frequency helps to avoid satellites

- Time saving

- Perfect adaptation of the valve to the dispense medium with software based programming of tappet movement

- Precise drop forms and highest process repeatability

© copyright 2025 VERMES Microdispensing GmbH