Micro Dispensing System - Types of Nozzle Inserts

Nozzle Inserts for the MDS 3000 Series and the MDS 1000 Series

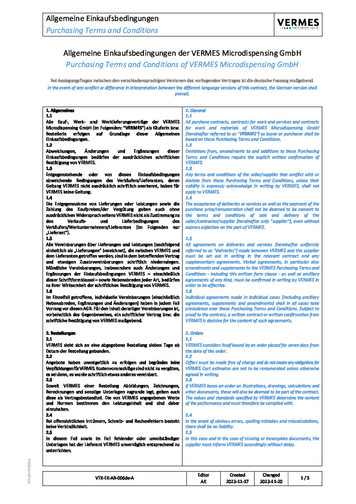

N-Type Nozzle Insert

N-Type Nozzle Inserts are the most commonly used NIs. There are a number of different models to choose from.

Description:

- Dispensing is done generally close to the substrate

- It allows a wide range of parameter settings

- Easy to handle

- Many different nozzle insert shapes and sizes are available

- Several variations of the inner channels (step bores, conical bores) are available

- The nozzle insert is offered in 1.75 to 4 mm lengths

- The customer can choose orifice diameters from 30 to 1200 μm

- Precision machined, meeting exact specifications

- Reusable nozzles reduce changeover time in the production line as well as waste of consumables

- The nozzle inserts deliver precise deposit control in complex applications, such as LED potting, under fills, fine-line bonding, edge sealing

- Serial number laser marked include lot numbers for process control and traceability

- Reduced back pressure to ensure full deposit

- Longer dispense life, even when used to dispense abrasive, particle-filled materials

- Achieves deposits as small as 50 μm for critical applications

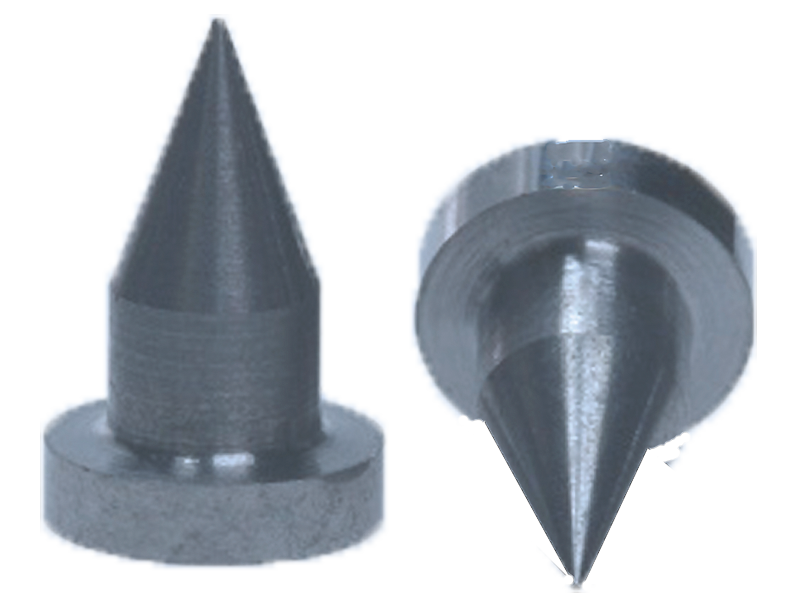

J-Type Nozzle Insert

J-Type Nozzle Inserts are mainly used for long distance dispensing and dispensing into cavities or grooves. There are a number of different models to choose from.

Description:

- Dispensing can be carried out from longer distance to substrate

- Wide variety of forms and sizes are available

- Variations in the inner channels of the nozzle insert (Step bores, conical bores available)

- Dispenses into cavities or grooves or works around other kinds of barriers

- The customer can choose orifice diameters from 30 to 1200 μm

- Double and single tapered outer counters

- Possible of dots, lines, or special patterns while reducing fluid stringing or tailing tendencies

- Nozzle inserts deliver precise deposit control in complex applications, such as LED potting, under fills, fine-line bonding, edge sealing

- Serial number laser marked include lot numbers for process control and traceability

- The long tube design allows for fluids to be easily dispensed into hard to reach areas which conventional dispense tips cannot reach

C-Type Nozzle Insert

C-Type Nozzle Inserts are made of PEEK and other stainless materials and are therefore perfect for low viscous media dispensing of medical and pharmaceutical applications.

Description:

- C-type nozzle inserts are a combination of the materials PEEK and HM and have a stainless cannula

- Each stainless steel tip consists of a precision stainless steel cannula

- Dispensing can be carried out from a longer distance to the substrate

- Mostly suitable for the low viscous materials

- The metal free nozzle inserts are perfect for applications in the medical industry

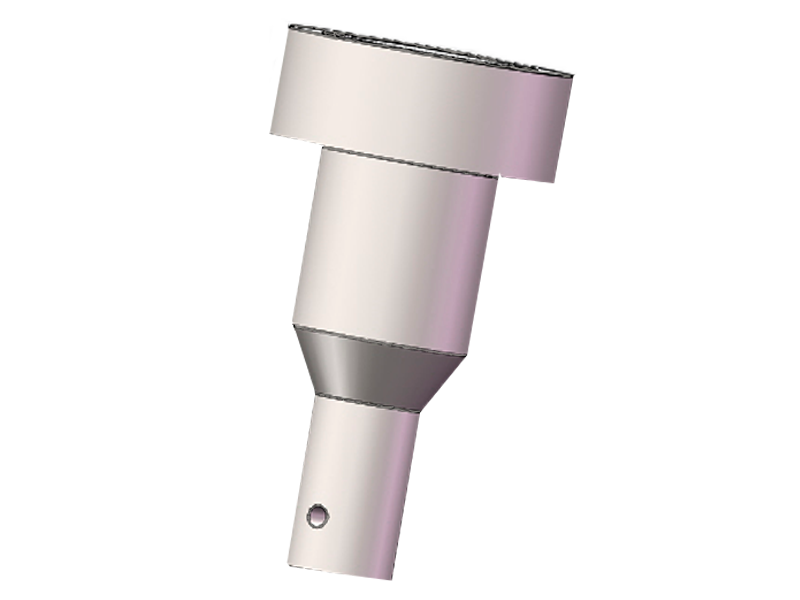

P-Type Nozzle Insert

P-Type Nozzle Inserts are the solution for side angle dispensing applications.

Description:

- P-type nozzle inserts are made of a combination of metal and plastics

- This nozzle insert type is perfect for a side angle dispensing (90°, 80°, 70°)

- The P-type provides low cost and interchangeable inlays

Download our Customer Newsletters

Corporate Overview

Powered by DST - Dynamic Shockwave Technology

with MDS 1560 System

Ultra-precise, contact-free dispensing with

high speed Piezo technology

Designed for all types of hot glue adhesive applications