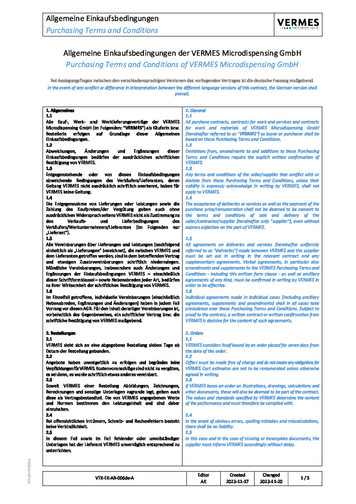

Micro Dispensing System - MDS 3080

The MDS 3080 system uses advanced piezo technology for superior dispensing of low to medium viscosity media. Its tappet position sensor simplifies process control and adjustment, ensuring high precision and thermal stability.

Fully compatible with all existing VERMES Tappets, Nozzle Insert, and accessories, the MDS 3080 features a modular and flexible design.

- Powered by VERMES PX2 - Piezo Xtreme 2 Technology

- Bayonet fluid box body for tool-free assembly and disassembly

- Compatible with all VERMES tappets, Nozzle Inserts, Heaters, etc.

- Easy adjust and process control with Tappet Position Sensor

- Retrofit to air-cooling possible

Major Advantages

Advanced PX2 Technology: Delivers exceptional precision and control, ensuring consistent, high-quality results.

Superior Precision and Thermal Stability: Offers reliable performance in high-precision operations and challenging conditions.

Adaptable Air-Cooling Retrofit: Allows easy retrofitting to air-cooling for enhanced adaptability.

User-Friendly Tappet Position Sensor: Simplifies adjustment and process control for optimal performance.

Versatile Interchangeable Tappet: Compatible with all VERMES tappets, simplifying maintenance and boosting flexibility.

Innovative Bayonet Fluid Box and “Top Adjust”: Ideal for low-frequency, low-viscosity applications without a temperature sensor.

Effortless Tool-Free Maintenance: Enables quick, hassle-free assembly and disassembly, reducing downtime.

Application Examples:

These include micro dispensing applications in:

Pharmaceuticals: Precise dispensing of active ingredients and coating .

Aerospace: Accurate application of adhesives and sealants in component assembly.

Food & Beverage: Sterile and precise dispensing of additives and flavorings.

Renewable Energy: Sub-nano accuracy in the production of solar cells and batteries.

Consumer Electronics: High-precision dispensing for the assembly of micro electronic devices.

Recommended Media:

The MDS 3080, featuring a unique Bayonet Fluid Box Body, offers exceptional flexibility and compatibility with a wide range of VERMES components, including nozzle inserts and tappets. This design ensures the system delivers the highest accuracy and superior media compatibility with medias of Low to Mediun viscosity, such as:

- UV Glues

- Cyanoacrylate

- Anaerobic Glues

- Organic Solvents

- Solder Flux

- Selective Coating

- Oils

- Greases

- Lacquers

Download our Customer Newsletters

Corporate Overview

Powered by DST - Dynamic Shockwave Technology

with MDS 1560 System

Ultra-precise, contact-free dispensing with

high speed Piezo technology

Designed for all types of hot glue adhesive applications